Oil & Gas Equipment Manufacturer Continues Partnership with Cybernet

-

PREMIER COIL SOLUTIONS, INC.

- Industry: Industrial

- HQ: Waller, TX

Challenge

Challenge

Premier Coil manufactures massive coil tubing, and pumping systems in a football field sized facility at their corporate headquarters. The equipment that they build has many moving parts and sensors that need a controller connected to an HMI panel so an operator can stay on top of things in real time as the equipment is functioning in the field.

The field was also a challenge for Premier Coil, as they needed a device that could withstand the rigors of some of the harshest environments imaginable, where their equipment is used. A rugged design that is shock and vibration proof for smooth operations.

Lastly, because the units would be mounted in an IP68 sealed box, they needed to find a rugged unit with terminal blocks capable of remote on/off functionality. And of course, they needed a device with the processing power and RAM to run their operating software.

Solution

Solution

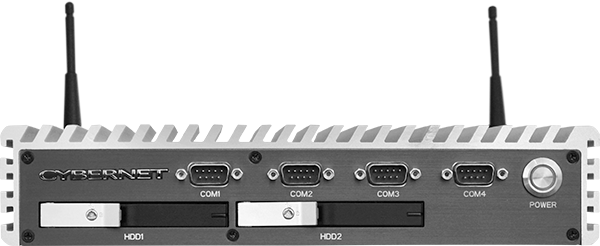

One of the lead engineers at Premier Coil had come over from a different company that had been using Cybernet devices. Knowing that their units had held up well on oil rigs and other drilling platforms, he suggested Cybernet as a potential solution to Premier Coil’s needs. And that is when they were introduced to the Cybernet iPC R2ix.

From a technical standpoint, the iPC R2ix had enough horsepower to efficiently collect and process data and run their software. Connecting to an HMI panel was a breeze, thanks to the many different display ports. The terminal block was the most critical piece, as it would allow them to mount the device in a sealed enclosure for remote on/off.

The next question was how the devices would perform in the field. Thankfully the iPC R2ix was IEC60068-2-27 certified for shock and vibration, was fanless, and was rated for operation in extreme temperatures. Seeing how Premier Coil’s heavy equipment would be deployed from Saudi Arabia to Alaska, extreme temperatures are par for the course.

Results

Results

Premier Coil has been integrating Cybernet devices for approximately four years now and can’t recall a single hardware failure reported by any of their customers. While no hardware deployment is completely devoid of hiccups, Premier Coil had full access to Cybernet’s engineering team during the evaluation and early development of their product to help overcome any and all challenges.

As Premier Coil now begins to move into the next generation of their equipment, they have started to evaluate the Cybernet iPC R1s, which provides a little more processing power and three video outputs for enhanced monitoring and operations.

There’s a couple of components in our equipment where we’ve had to go back to the vendor because it wasn’t holding up. But we’ve had no issues with the Cybernet units. I’d have to go back into the archives, but I can’t recall a single hardware failure.

- S.J., Electrical Engineer

PREMIER COIL SOLUTIONS, INC.